As a "creator of work environments," Aichi Corporation has changed the environment of a variety of workplaces.

Here are some of the ways in which it has affected and contributed to the electric power, communications, shipbuilding, construction, and railroad industries.

Electric power industry

Transformation of conventional power distribution work

Release to market of digger derricks, pole setters, and digger derrick / pole setters. This greatly improved the efficiency of pole setting work, which had previously been done by man power. Power distribution work, which had been done by people climbing electricity poles, was mechanized using aerial vehicles. This dramatically reduced incidences of electric shock, which had previously been a top priority task. In addition, aerial vehicles were able to vary their height or workplace and also rapidly improved work efficiency. This also contributed to the spread of the “live-line working method” for performing engineering work without stopping the electricity.

Before mechanization, man power was at the center of every worksite.

Today, work to achieve improvement in safety and cost reduction is being performed by aerial vehicles.

Communications industry

Contribution to eliminating deaths in falls

At the time, work was generally performed while stabilizing the posture by a safety rope.

With the aerial vehicle, climbing utility poles became no longer necessary.

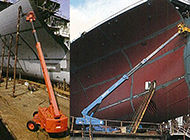

Shipbuilding industry

Realization of the non-scaffold construction method

The work of assembling scaffolding for erecting and razing required a lot of time.

Work efficiency is significantly improved without the need to assemble scaffolding.

Construction industry

Achievement of shorter construction times

Improved work efficiency as "mobile scaffolding."

Small type for moving freely between floors.

Railroad industry

Improvement of work mobility

Railroad construction must be performed during limited nighttime hours.

Work faster with a train wheel drive system.